Solid-state light sources are much more efficient than arc-discharge lamps at converting electricity into light. That’s a fact. However, because like any light source, the light output and lifetime of the sources both decrease with increasing temperature, the removal of heat generated in the process remains a critical engineering requirement.

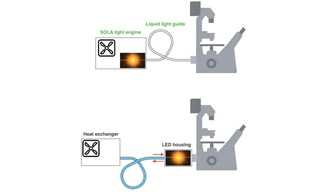

Typical Lumencor Light Engines used for fluorescence microscopy generate watts of light output. A liquid light guide is used to deliver that light to the microscope, without transmitting vibrations emanating from the cooling fan. This solution, implemented in all our SOLA, SPECTRA, SPECTRA X and AURA Light Engines, is depicted in the upper panel of the graphic. In an alternative engineering solution, shown in the lower panel, the light generation and heat dissipation functions are performed by two separate but coupled modules. This dispenses with the need for a liquid light guide at the expense of adding a circulation hose to carry pressurized cooling fluid between the heat exchanger and light generation modules.

At Lumencor, our adoption of the on-board heat exchanger plus liquid light guide stems from three overriding considerations:

- Minimum separation between a heat source and a dissipation conduit maximizes cooling efficiency and reliability.

- A passive liquid light guide is more robust than a pressurized liquid circulation system.

- Perceived deficiencies of liquid light guides are largely derived from their use with metal halide lamps. They are simply not relevant in the context of solid-state Light Engines.

At Lumencor, we’ve sold many thousands of light engines and have not replaced even one light guide due to over heating, leaking or bubble formation. Our customers can confidently testify that they have never replaced a liquid light guide on a Lumencor Light Engine... that can be a significant cost savings over the long lifetime of these solid-state lighting products!