Fabrication of Biomimetic Structures by Patterned Ultraviolet Photopolymerization Using the SOLA Light Engine

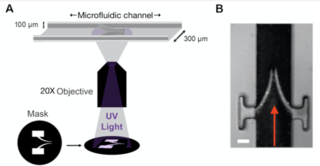

Solid state microscope light sources are ideal for controlled initiation of photopolymerization reactions1, which are the basis of widely used techniques for non-contact, in situ fabrication and molding of microscopic structures. For example, a recent publication from a research team at the University of Birmingham2 described the use of photopolymerization of polyethyleneglycol diacrylate (PEGDA) to fabricate in vitro models of bicuspid venous valves inside microfluidic channels. The technique is outlined in Figure 1. Ultraviolet light from a SOLA Light Engine was passed through a mask that defines the contours of the valve. The extent of PEGDA polymerization and therefore the elasticity of the model valves was controlled by varying the UV exposure time or the concentration of photoinitiator. Ghost particle velocimetry (GPV), a bright field light scattering technique, was used to map the flow of aqueous nanoparticle suspensions in the proximity of the flexible valves. The findings provided insights into the effects of flow patterns around the valves on the pathogenesis of deep vein thrombosis (DVT). Notably, the capability to fabricate valves with leaflets of different elasticity revealed how asymmetrical stiffness links to the aggregation of particles behind the valve leaflet, replicating the association typically found in vivo.

Figure 1. (A) Fabrication of model venous valves by patterned photopolymerization of PEGDA. Controlled polymerization is driven by UV light from a SOLA light engine in the presence of the photoinitator 2-hydroxy-2-methyl propiophenone. (B) Image of a model bicuspid valve. Red arrow indicates the direction of fluid flow. Scale bar = 100 μm. Reproduced from Schofield et al. (2020)2 under the terms of the Creative Commons Attribution License.

- Apr 14, 2021